This is an excerpt from the Book called “Drywall Received” by W. Robert Harris. Continue reading to learn more about Drywall Furring Channel Ceilings, thanks to the author.

Suspended drywall ceilings constructed with drywall furring channels are used in high-rise buildings and in other types of commercial structures. The light-gauge metal framing components provide a lightweight, noncombustible framing system suitable for drywall application. The ceiling framing assembly consists of drywall furring channels which are wired tied, screwed, or clipped to 1 ½” cold-rolled steel carrier channels. The carrier channels are suspended from the overhead structure of a new building or from the existing ceiling framing of an old building using No.8 hanger wires.

The following six steps are recommended and should be followed when constructing suspended furring channel ceilings, providing the hanger wires have been previously installed:

- Determine the finished ceiling height from the plans. The finished ceiling height is the height of the ceiling after the drywall sheets and any other covering have been applied.

- Subtract the thickness of the drywall sheets and any other covering to determine the rough ceiling height. The rough ceiling height is the height of the ceiling before the drywall sheets and any other covering have been applied. This is necessary for determining the finished ceiling height, since other materials such as acoustical tile may be applied to the drywall. For example, a set of plans indicate a finished acoustical ceiling height of 9’-6’. The ⅝” drywall sheets are to be covered with ¾” acoustical tile to form the finished ceiling. The ⅝” thickness of the drywall sheets added to the ¾” thickness of the acoustical tile equals a total thickness of 1⅜”. When 1⅜” added to the 9’-6” finished ceiling height, the rough ceiling height is 9’-7⅜”.

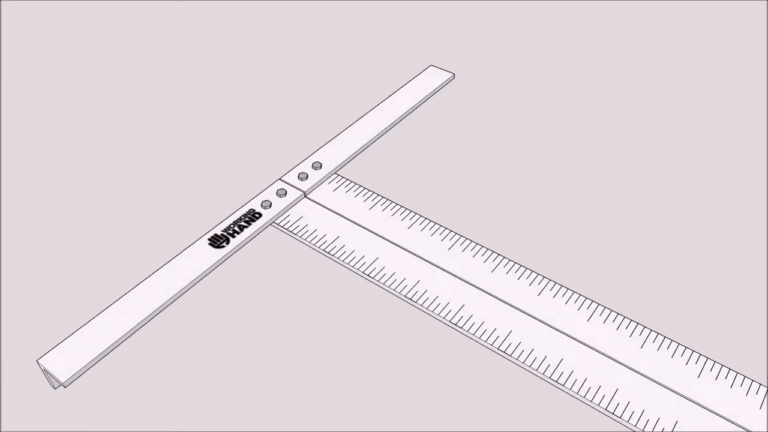

- Measure and mark this location around the room with the aid of a laser or water level. This is the height to the bottom of the furring channels.

- Raise the laser ⅞” to allow for the thickness of the furring channels and place a 90° bend on each hanger wire.

- Lay the 1 ½ “cold-rolled steel carrier channels in the bend of the hanger wires. Hanger wires are spaced at intervals determined from the plans or as required by the AHJ.

- Wrap the channel twice and twist the wire around itself. Repeat this step until all carrier channels have been installed and all hanger wires have been wrapped and twisted.

- Lay out the spacing of the furring channels on the carrier channels.

After the alignment adjustments are completed, any hanger wires that have been moved away from dead center are secured with a wire tie or framing screws. This prevents them from sliding back to their original position and causing the ceiling to sag.

The completed ceiling framing is now ready for the other tradesworkers to perform their work. After the other tradesworkers have completed their work, the framer must inspect the ceiling to be sure that the members are intact and properly aligned, and the layout spacing has been maintained. If inspections are required by the AHJ, they may be ordered at this time.

The completed ceiling framing is now ready for the other tradesworkers to perform their work. After the other tradesworkers have completed their work, the framer must inspect the ceiling to be sure that the members are intact and properly aligned, and the layout spacing has been maintained. If inspections are required by the AHJ, they may be ordered at this time.

(816) 256-4284