A Drywall T square is a tool commonly used in engineering and drawing to ensure a straight line or edge, at right angles.

A drywall T square basically acts as a guide and support when cutting plasterboard,

A drywall T square is necessary for cutting and fitting drywall panels. Its main function is to provide a straight line or edge along which to cut drywall using a special utility knife.

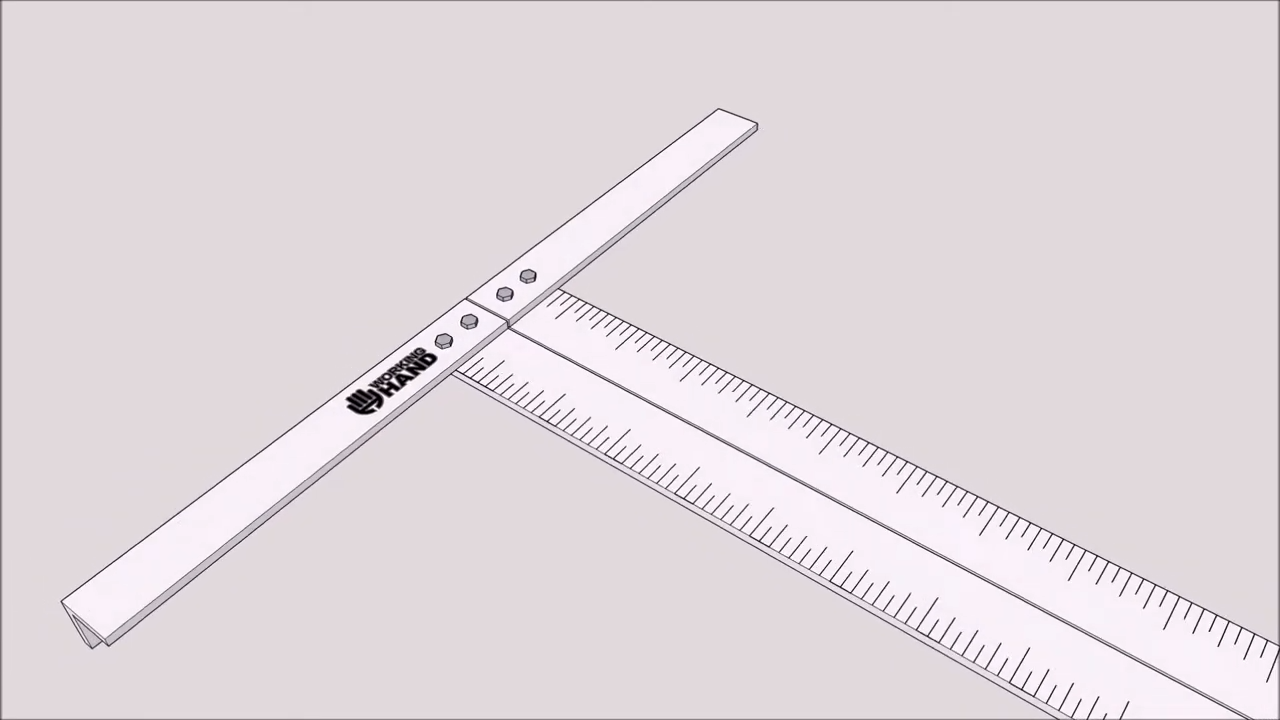

A drywall T square is typically larger than a standard T square because the surface it is used on is much larger than drawing paper. A typical drywall T square is made up of 2 parts; the ‘head’ or ‘stock’ which is the shorter shaft, and the ‘blade’ which is the longer shaft. A T square can be made of metal, plastic, or wood.

Here are a couple of things you should consider when purchasing a drywall T square.

Picking and Using Squares

These simple but crucial measuring tools can do some incredible tricks. When corners converge at 90 degrees, walls stand straight, windows close tight, and drawers fit snugly every time. The secret to all this is using a square. Most square offer a fixed 90-degree angle in various shapes, and some can help you draw or create other angles as well.

“The first square you purchase should be a 12-inch speed square. It’s durable and versatile. It offers you 90- and 45-degree angles, and also doubles a ruler. Not only that, but it’s also easy to draw other angles with it as well.”

When choosing squares, a person must consider where exactly the tool is going to be used. Material type, thickness, width, and blade length are all crucial factors to consider, as they determine the suitability of a square for different applications.

You’ll come across many types of squares at your local Home Depot, but you don’t need to buy all of them. Start with the basic models we show here to measure and cut; and proceed to use specialty squares, like a sliding T bevel or a drywall T square, when the task requires it.

Using Drywall T Square

Establish the square of the plasterboard by aligning the edge of the material with the stock.

Identify your cutting points and mark them using the markers along the blade.

Holding the T square firmly, use the blade as a guide to slice the board along your marks.

How to cut plasterboard with a drywall T square

To cut or slice plasterboard, you will two tools; a trimming/utility knife and a drywall T square.

Step 1: Measure

Determine the exact place where you need to make a cut on the plasterboard using your square.

You can cut the plasterboard flat or with the sheet standing up. When using a drywall T square, it’s advisable to cut with the sheet standing up.

Step 2: Place drywall square

Place the drywall square on top of the plasterboard so that you can cut straight down the front side of the sheet against the square, resulting in a clean, straight edge.

Step 3: Cut the board

Cut the board in a downward direction, stopping about two thirds of the way. Next, complete the cut in an upward direction. Cut through the paper and into the inner core, about a third of the way through the board. The plasterboard should then snap easily into two.

Step 4: Finish the cut

Finish the cut by scoring the rear paper along the fold with your trimming knife, so the board is fully cut.

A drywall T square may also come in handy when hanging plasterboard. You can use it to line up where you will screw the studs into position.

Types of Squares

Sliding T Bevel

The moveable blade allows you to copy and angle and paste onto lumber, moldings, or other materials. It won’t measure the angle, but this is not necessary as an exact match is what you want. You can use a sliding T bevel with a compass to divide angles for mitering.

Drywall Square

A drywall square has a 4-foot blade that makes it ideal for making cut lines on regular sheets of drywall, plywood, and other board materials. You can also use it as fence (guide) when slicing drywall.

Try Square

Cabinetmakers use the try square to check edges and corners, but for most carpentry work, a combination square is more suitable.

Speed Square

A speed square is a compact right triangle with a base includes a flange that you can attach to an edge you are working on, allowing you to draw a 45-degree miter or an accurate square cut line. The other edge has markings for making stair, roof trim and rafter angles.

Framing Square

Made up of a short, narrow tongue and a long blade, this L-shaped square is useful when making marks on sheet stock and wide boards or verifying the squareness. It also comes in handy when laying out stair stringers and rafters. Ruler measurements (in 1/16, 1/12, 1/10, and 1,8) are printed both the outside and inside edges; be careful to read the correct measurement and side.

Square Tricks and Tips

Checking a square for accuracy

Before using a framing square (or a try square or combination square, for that matter), make sure it’s accurate. Align the tongue on a straight edge and draw a line down the blade. Next, flip the tongue over along the edge and draw another line down the place in the same place. If the lines make a narrow V or X, the square is off. The lines should be perfect parallel lines for maximum accuracy.

Finding the center of a circle

Begin by placing the corner of a framing square on any point on the edge of the circle. Next, mark where the tongue and blade leave the circle. Connect these two points with a straight line, then move the square and do it again. The point where the two diameter lines intersect is the center of the circle.

How do you hold a T Square?

Place the T square at a right angle along the edge of the board.

A T square has a straight edge that can be moved and can support other working tools like squares and triangles.

The T square can be moved across the board to the specific place where one wants to draw.

Conclusion

Now that you know a lot more about drywall T squares, I’m confident that you feel more confident when buying and using a T square in your projects.

Call Citi Drywall Repair In Kansas City, MO to get the best ever drywall repair service in the city at (816) 256- 4284.